Process Hazard & risk Analysis services

Risk analysis and management is the core of our services at Process Risk and the basis for several key industry regulations. For over 35 years, Process Risk consultants have performed hundreds of risk analysis most of which begin with PHA studies. We have conducted PHAs in all major industries using various methodologies. Our world-wide experience ranges from project PHAs, FEED phase studies through design stage PHAs, re-dos and revalidation PHAs, Management of Change (MOC) PHAs as well as procedural PHAs. We have expertise with all industries and systems. We also perform advanced level studies such as Layer of Protection Analysis (LOPA) and a full range of Safety Instrumented Systems (SIS) services.

Process Hazard Analysis (PHA)

Hazard identification and analysis uses team knowledge, checklists of hazards and process information to determine process, and facility characteristics that could pose safety or environmental hazards that can lead to undesirable consequences. Read More

Safeguard Protection Analysis (SPA)

Safeguards protect processes from process safety incidents. They are critically important and consequently, every effort must be exerted to ensure they are functional, effective, and adequate. A focused review of identifed safeguards is now required in certain US regulations. Read More

Layers of Protection Analysis (LOPA)

LOPA is considered a more quantitative risk assessment method than a PHA study. It provides an objective, rational and reproducible method of evaluating the risk of hazard scenarios and comparing it with risk tolerance criteria. It is often linked to the results of an associated PHA study. Read More

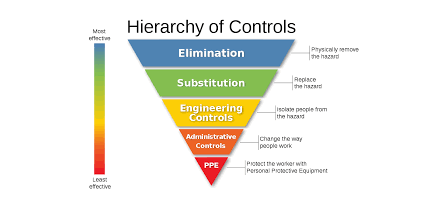

Hierarchy of Controls Analysis (HCA)

Various types of controls are used in process safety management to manage the risks of catastrophic events in processes involving highly hazardous materials. Certain types of controls provide a more reliable means of controlling risk than others. A review of all control options is a more recent expectation in some state regulations and best practices. Read More

Human Factors Review and Analysis

Human factors are considerations that can impact any operation or the performance of any trained staff. People are key components to the safe operation of industrial processes. They are involved in process design, operation, maintenance, etc. Identifying factors that can adversely impact human operation is key to having a well managed safety program. Read More

Inherently Safer Technology (IST)

Inherently Safer Technology (IST) can enhance overall chemical safety and security risk management programs. This concept has become a requirement in select state regulations as well as gaining exposure throughout all industries. Benefits can be realized from new projects to existing processes. Read More

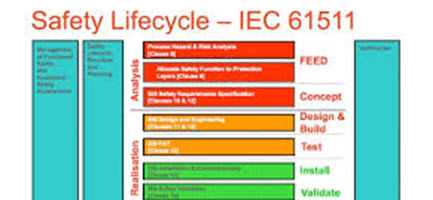

Safety Instrumented Systems (SIS)

ANSI/ISA-S84.00.01-2003, (IEC 61511 Mod), Application of Safety Instrumented Systems for the Process Industries, (called IEC 61511 / ISA 84 here) addresses the application of Safety Instrumented Systems (SIS) ds are needed... Read More

Quantitative Risk Assessment (QRA)

Various types of controls are used in process safety management to manage the risks of catastrophic events in processes involving toxic... Read More

Facility Siting & Consequence Modeling

OSHA PSM and EPA RMP include requirements to address facility siting. Facility siting is comprised of several components tied to PHA studies as well as full site consequence modeling including building evaluation, consequence analysis and building risk assessment for the site. Read More

Simultaneous Operations (SIMOPS) Review

Simultaneous operations (SIMOPs) are situations where two or more operations or activities occur at the same time and place in a facility.... Read More

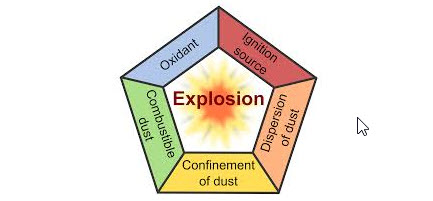

Dust Hazard Analysis and Management

NFPA 652:2016, Standard on the Fundamentals of Combustible Dust, requires that a safety management system (SMS) address the hazards of combustible dusts. Read More